Client: Toronto Transit Commission / City of Toronto

Services: Hydraulic Study, Detailed Design, Contract Administration, Inspection assistance during construction, Post-Construction Services

Key Features:

• A hydraulic study was conducted to access potential impacts on the flow capacity of the existing Low Level Interceptor due to the proposed sewer alignment change.

• CFA developed a new innovative design for a rectangular steel panel primary liner since one was not available on the market for this flat rectangular tunnel configuration.

• A major intersection with extremely heavy traffic and complex services and utilities, some 16 or 17 pipes and conduits in each direction, were complicating factors in the project.

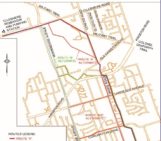

The construction of a second platform at TTC’s Union Station to the south of the existing subway made it necessary to re-locate the City of Toronto’s Low Level Interceptor sanitary trunk sewer along Front Street. It functions as part of a system of cross-town “interceptors” that lead to the Toronto’s Main Treatment Plant.

The existing 1050 mm wide x 1575 mm high upright box sewer section had to be converted to a flat section of 1800 mm wide x 900 mm high in order to get through the existing underground utilities.

In order to avoid the congestion of traffic and numerous utilities and services (the majority of which are in excess of 100 years old) and an ultimate depth of over six meters, tunneling by “hand-mining” was selected as the best option. A custom-designed steel plate primary liner with cement mortar grouting both outside and inside the liner was considered to be the most desirable for preventing any settlements. This tunnel method enabled a spur tunnel to be constructed for the connection of sewer lateral branches under the busy intersection.

A temporary flow-diversion strategy was critical for connections of the new realigned sewer with the existing system during construction.